CNC Turning

CNC (Computer Numerical Control) machining is a metal part manufacturing production process. CNC is performed in machines that operate on a variety of axes. Generally speaking, the more axes a machine uses in its production operations, the more intricate and detailed the part.

CNC Turning

CNC turning is a common process that produces not only long, thin parts, but also very fine and long parts. The process is used to produce parts for a variety of industries and has advantages over other processes such as metal injection molding because the final part is 100% dense metal. Many experts agree that the best way to obtain 100% quality metal parts is through machining. CNC turning combines two different manufacturing processes to make your products more competitive in the market by keeping costs as low as possible.

01. 3D Model

For customers who may not be able to actually grasp the real object because they only look at the 2D drawing, they can use the vivid method of “3D drawing” to understand the physical appearance of the real object, such as space setting and organization matching inspection, which can be presented more clearly.

02. With Right Material

Use with right material is related to product cost, and it is even more important for product function and service life. For various demands (such as impedance, hardness, drilling accuracy) we provide cheap and easy-to-obtain materials for customers to choose, so that the product has innate The advantage wins at the starting point.

03. Cheap and Free of Tooling

Cheap and free of tooling can provide customers with peace of mind on their initial investment, which in turn speeds up part build-out.

04. Rapid Production Capability

We have a 24-hour working environment and arrangements, and the rapid production mechanism can satisfy customers to quickly obtain samples and then test and verify and introduce mass production.

Let's Build Something Together

Real Results, Guaranteed

Case Studies

Professional and Experience

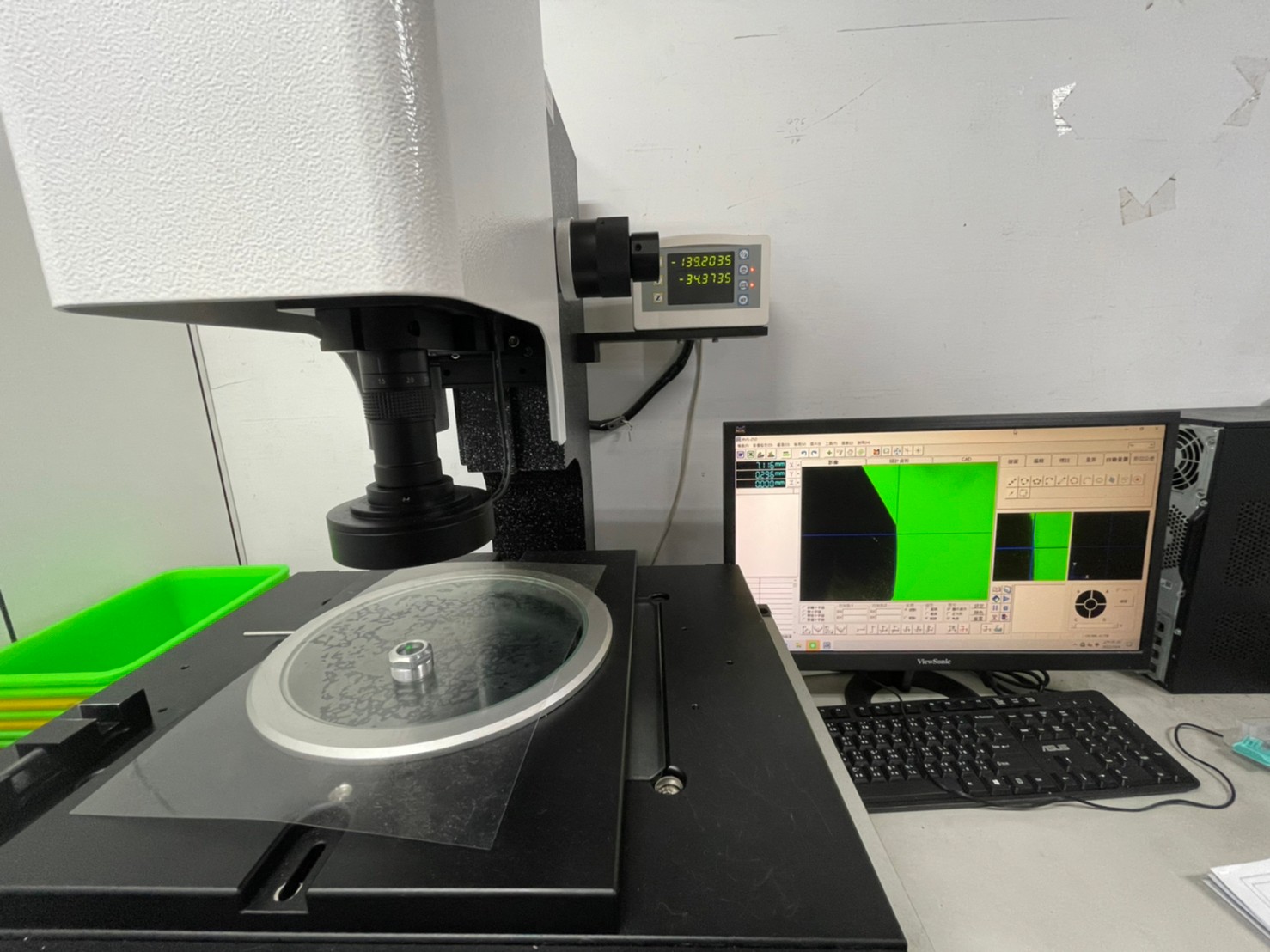

Inspection equipment

The pursuit of product consistency is the goal pursued by all CNC machine manufacturers. Therefore, the consistency and accuracy of CNC machines before leaving the factory is very important. We will use traditional measuring tools and measuring molds to measure CNC machines. , and plan a set of standard operation measurement methods, so as to review the standard operation process or assembly error or the problem of the machine structure, and change the mode of the problem point according to the problem type, so as to improve the static accuracy of the machine.

Let's Build Something Together

Trusted Manufacturer

Made in Taiwan

Engineers at ANYTRONIC® understand the complexities of beginning a new CNC Turning project and want to help you to bring yours to fruition. You can trust the experts at ANYTRONIC to take your product from concept to completion.

For more information on ANYTRONIC® CNC Turning and if it would be the right method for your part run, contact one of our manufacturing & engineering experts now.