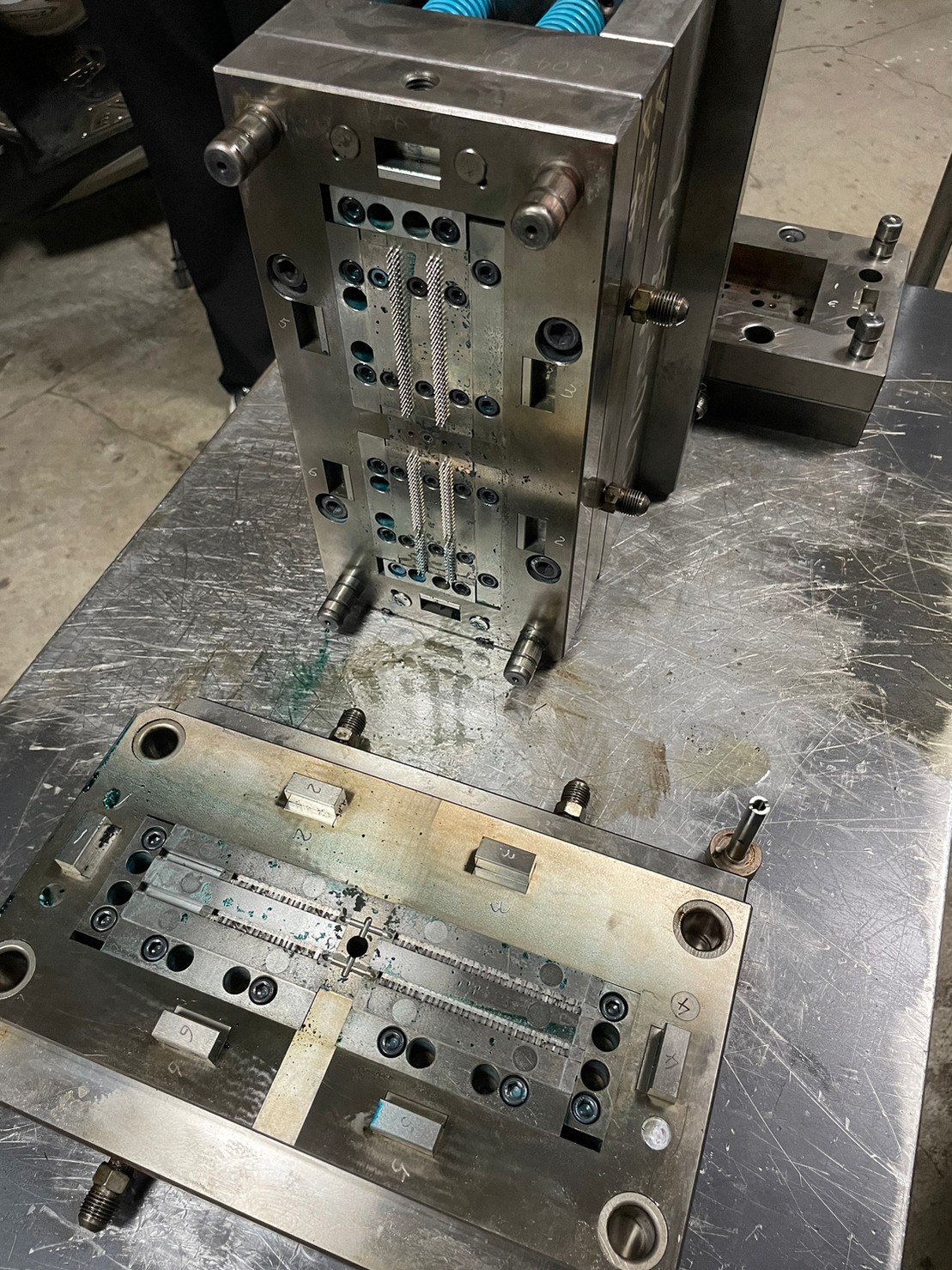

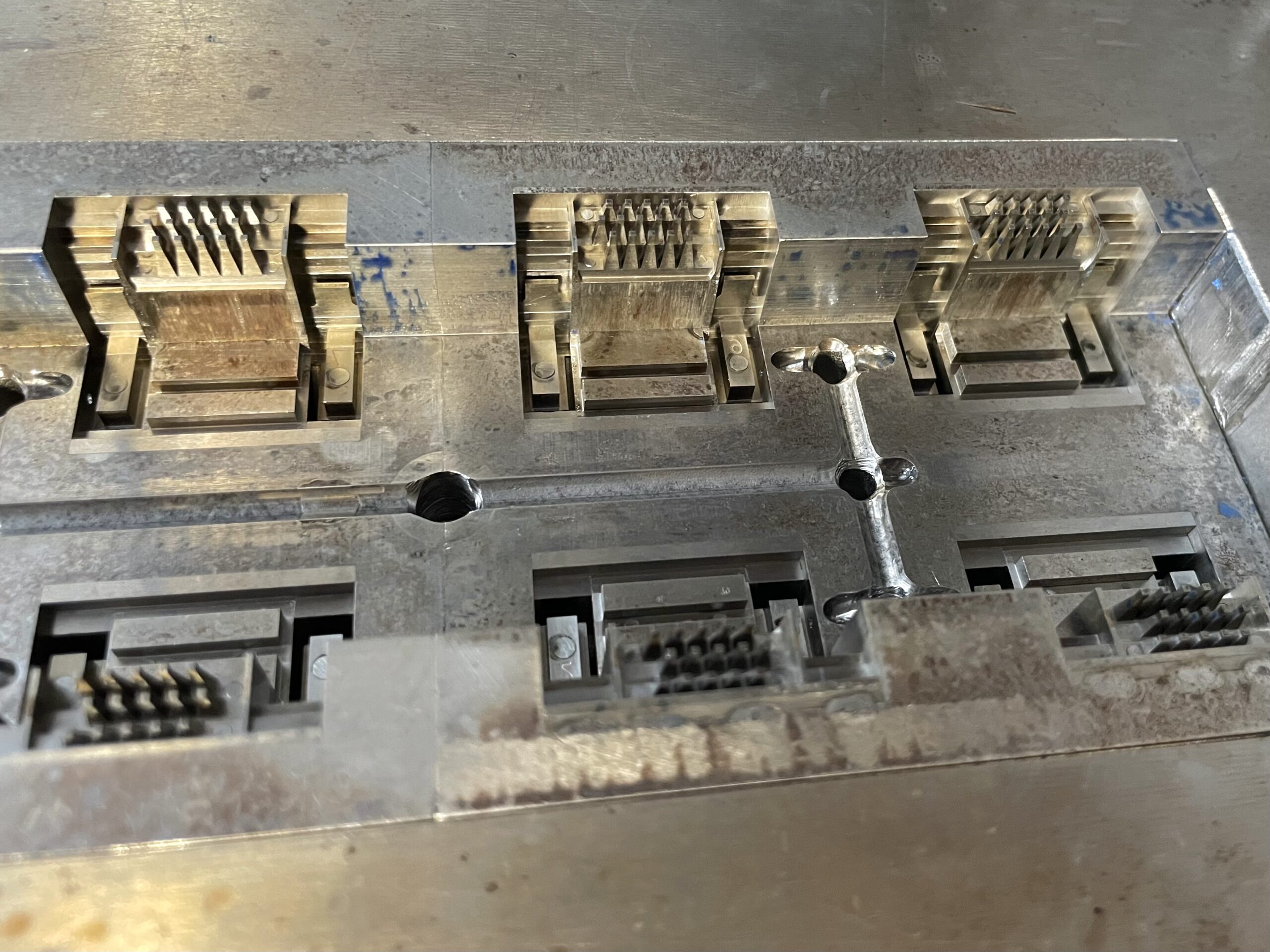

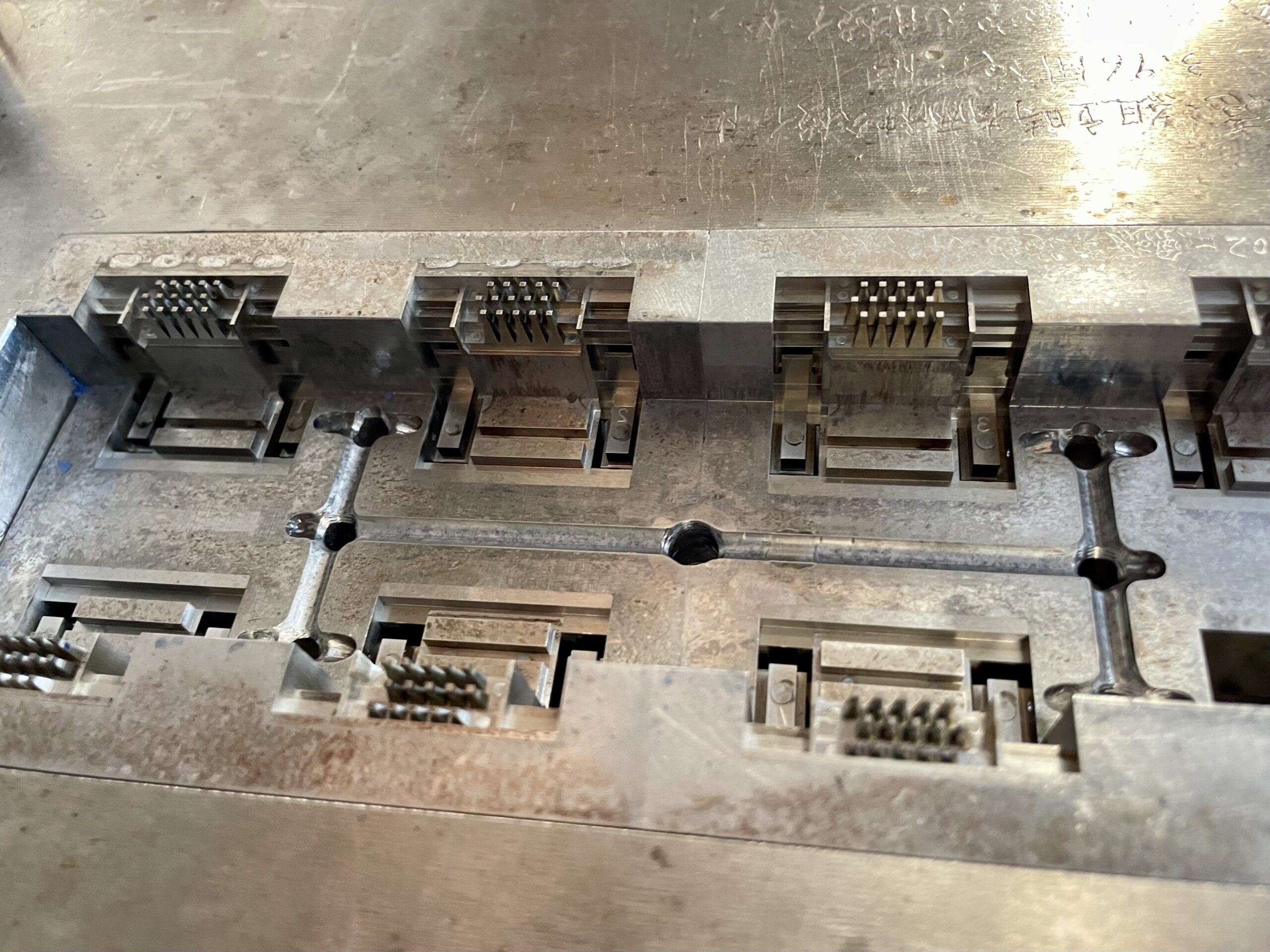

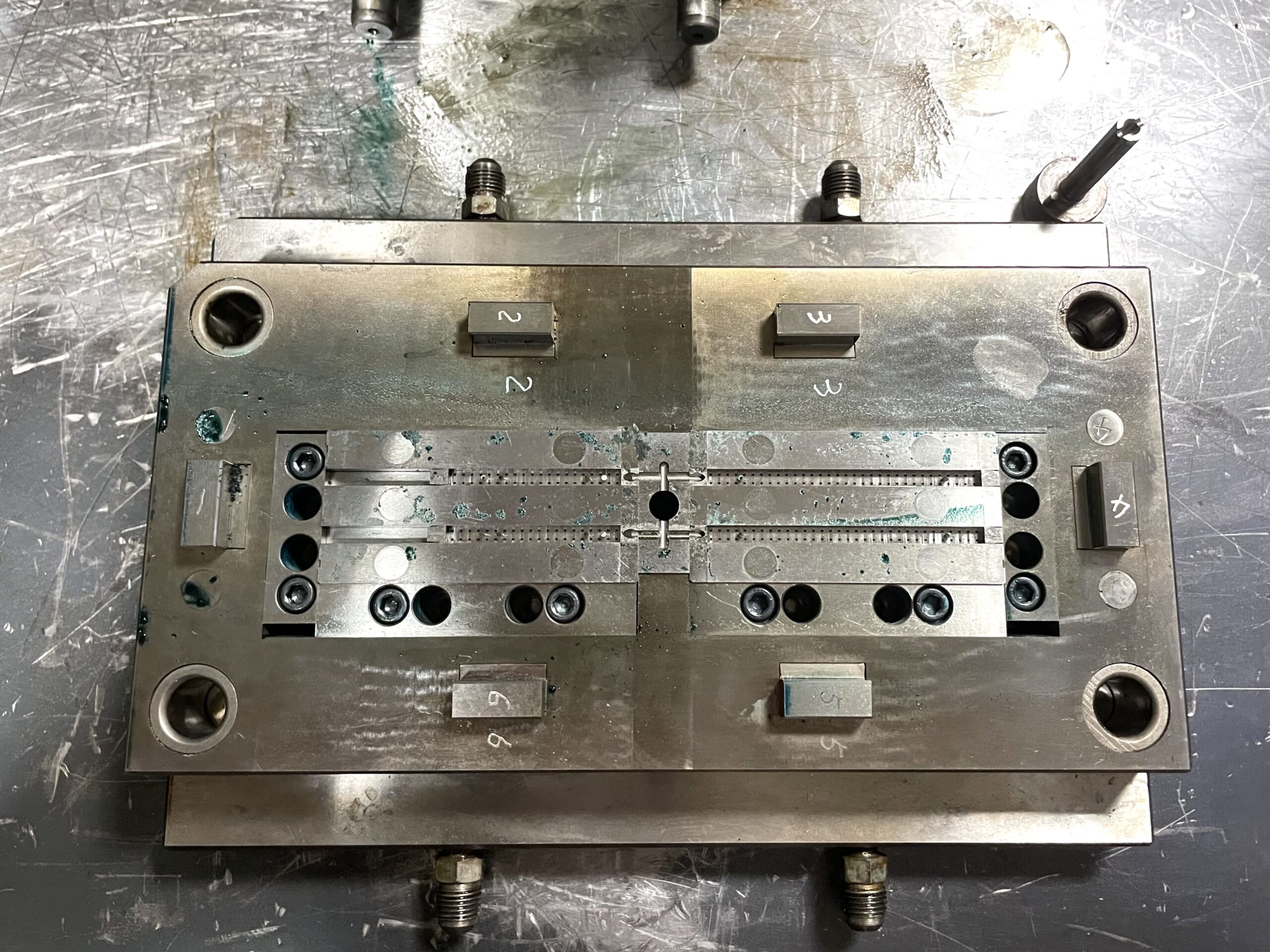

Injection Mold

Injection molding is a process in which a thermoplastic polymer is heated above its melting point, resulting in the conversion of plastic pellets into a molten fluid with a relatively low viscosity. This melt is injected into the closed mold with low temperature at a very fast speed through the nozzle at the front end of the barrel, and after a certain period of cooling and shaping, the mold is opened to obtain the product. Therefore, the design and manufacture of the mold directly affects the quality of the rubber core and whether the product is mass-produced or not.

Creating a New Mold

We are happy to submit production cost assessment, structural analysis, material suggestion, 3D MODEL, mold flow analysis, DFM REPORT, FAI REPORT to customers, so that the mold can meet the cost requirements and mass production on time.

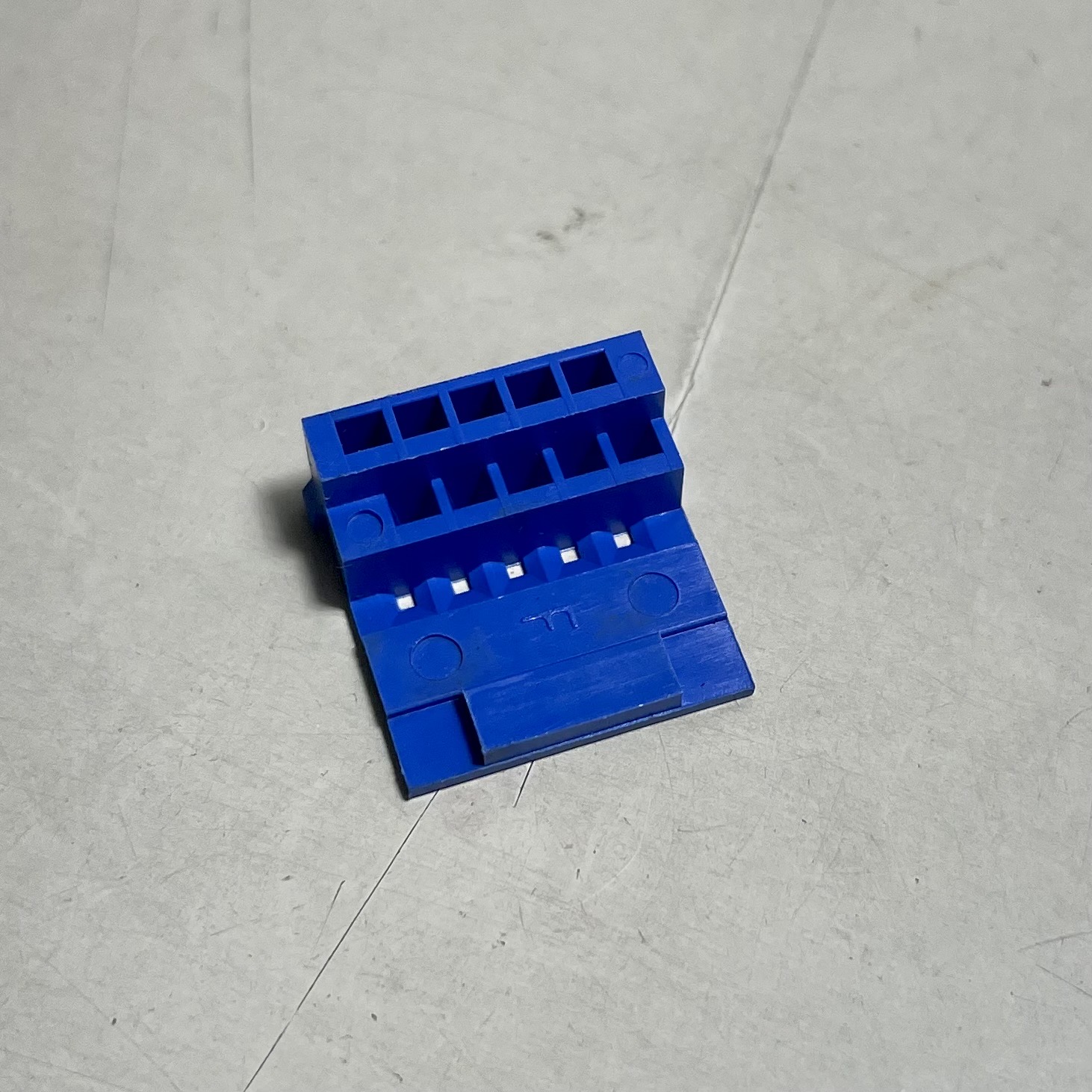

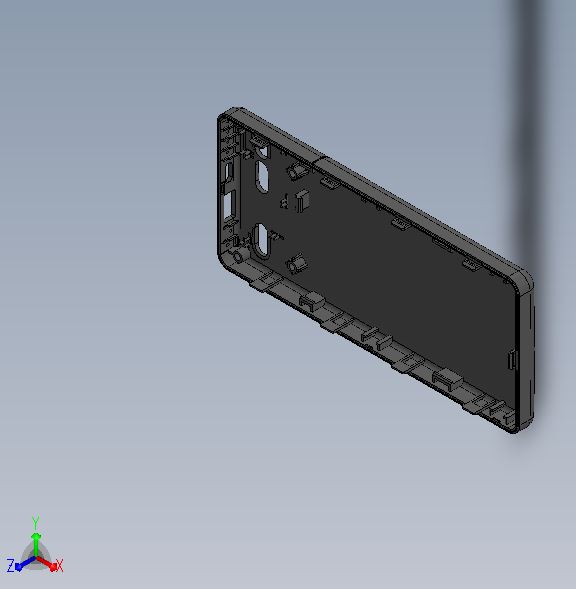

01. 3D Model

For customers who may not be able to actually grasp the real object because they only look at the 2D drawing, they can use the vivid method of “3D drawing” to understand the real appearance of the real object, such as space setting and organization matching inspection, which can be presented more clearly.

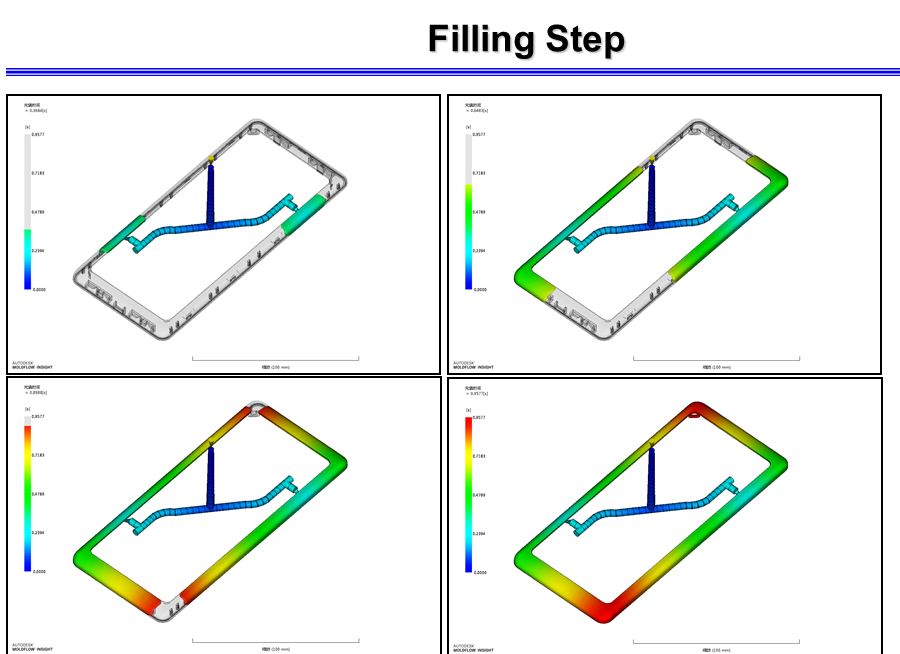

02. Moldflow Analysis

By using the mold flow analysis software to simulate the flow behavior of the actual injection molding, we can analyze and optimize the actual plastic products in the product design and mold design stages before production, so as to avoid possible quality defects during actual production, and then The number of mold repairs and mold trials is reduced, thereby shortening the time required to build molds and reducing manufacturing costs.

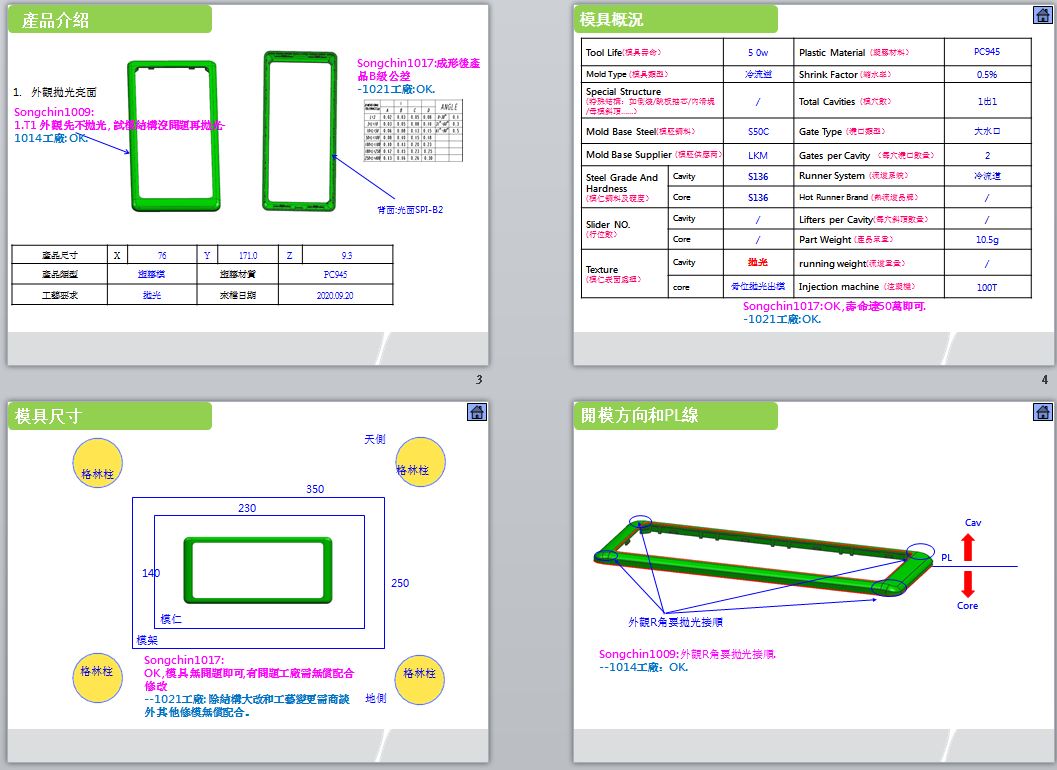

03. DFM Report

Design For Manufacturing mainly from improving the manufacturability and assemblability of the product, studying the relationship between the mechanism of the product itself and the manufacturing system, and using the inspection results in product design, fully considering product manufacturing and assembly in the product development stage The demand, by reducing product design modifications, reducing product manufacturing and assembly errors, improving product quality, reducing costs, shortening production time, and improving product manufacturability and work efficiency.

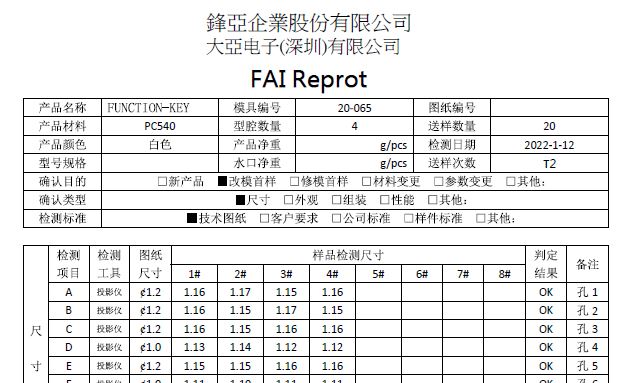

04. FAI Reprot

First Article Inspection, when manufacturing new parts or designing modified parts, conduct comprehensive testing and inspection on the first batch of parts produced or samples of the first batch of parts to ensure that all requirements are met, which enables us to satisfy customers with real understanding product status.

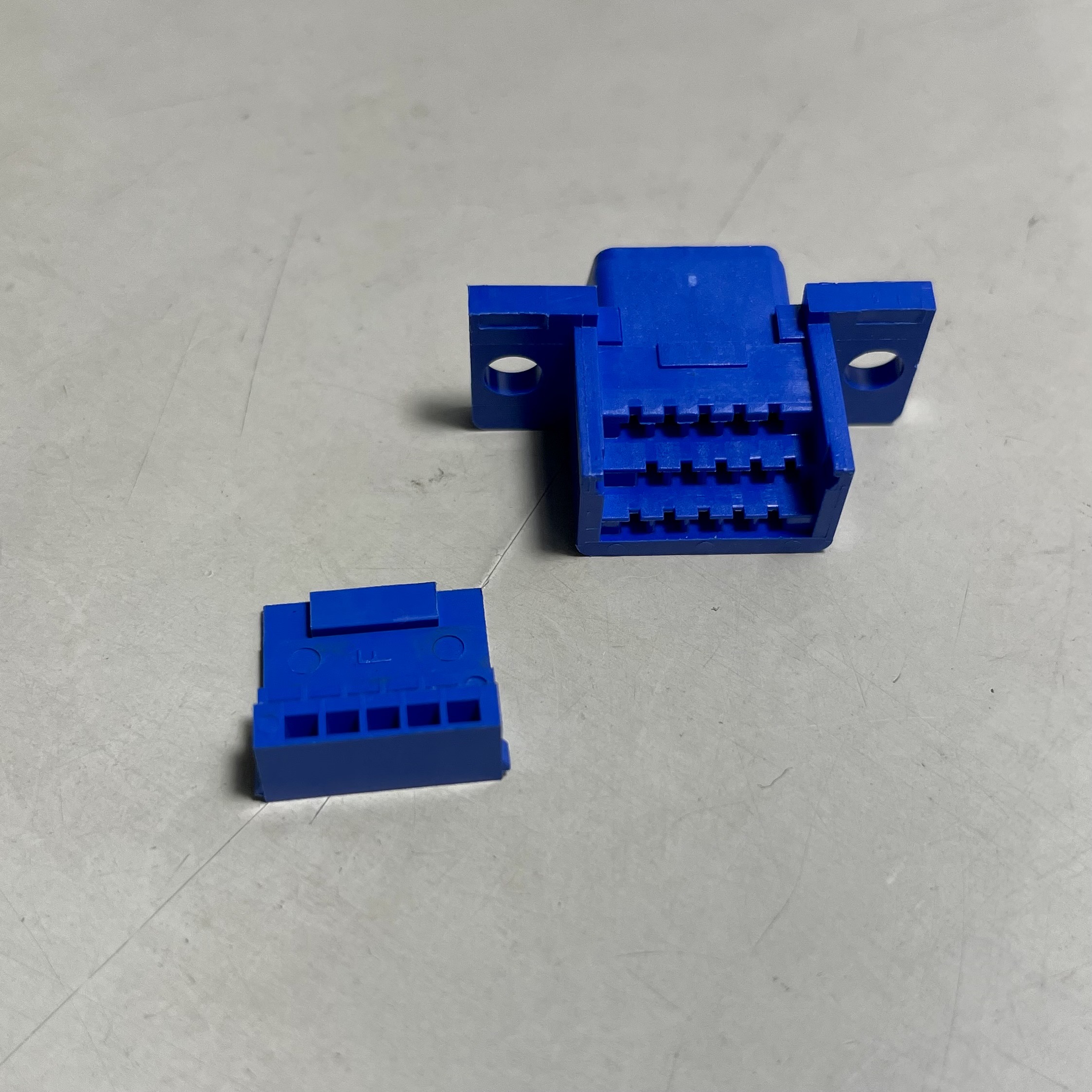

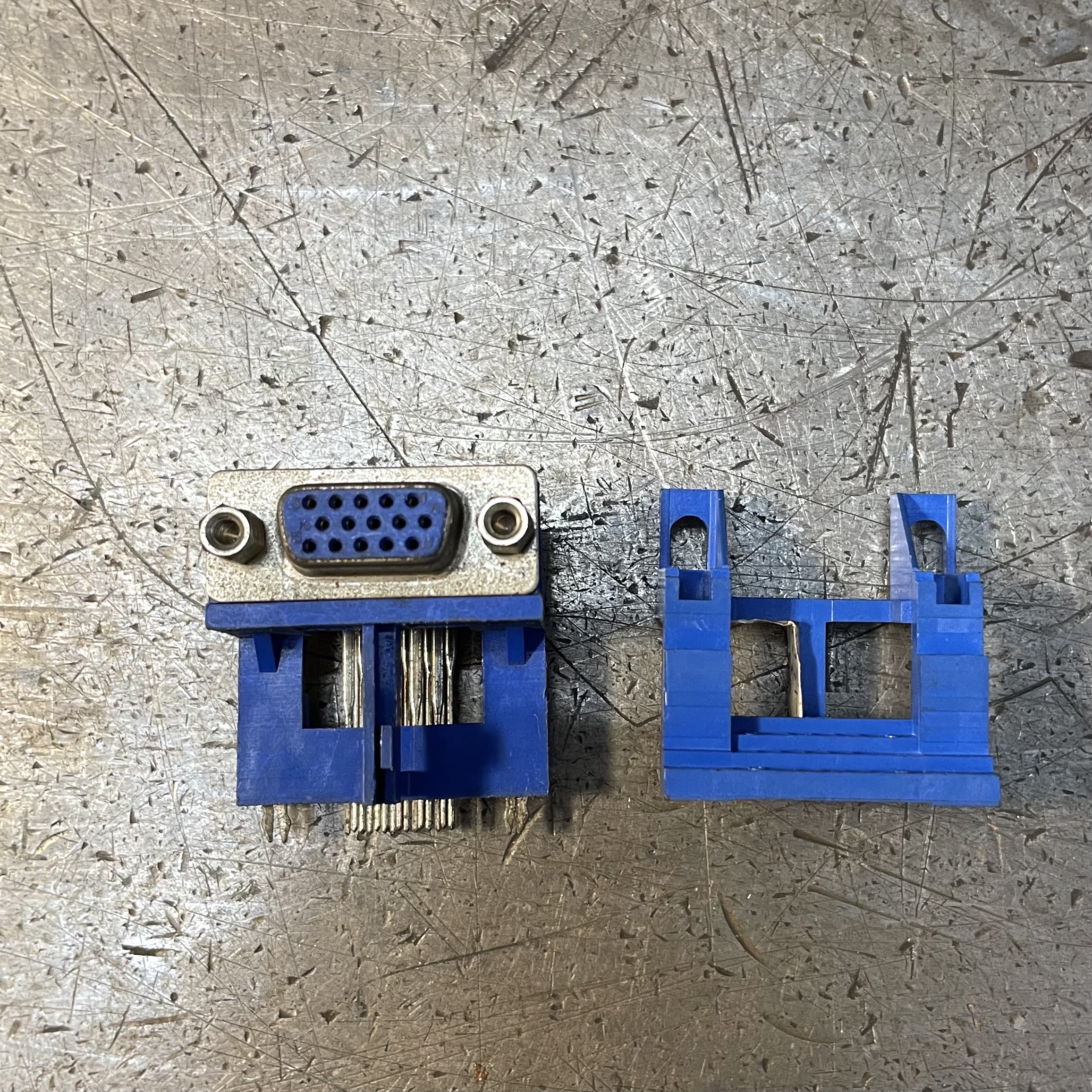

Real Results, Guaranteed

Case Studies

Let's Build Something Together

Trusted Manufacturer

Made in Taiwan

Engineers at ANYTRONIC® understand the complexities of beginning a new CNC Turning project and want to help you to bring yours to fruition. You can trust the experts at ANYTRONIC to take your product from concept to completion.

For more information on ANYTRONIC® CNC Turning and if it would be the right method for your part run, contact one of our manufacturing & engineering experts now.