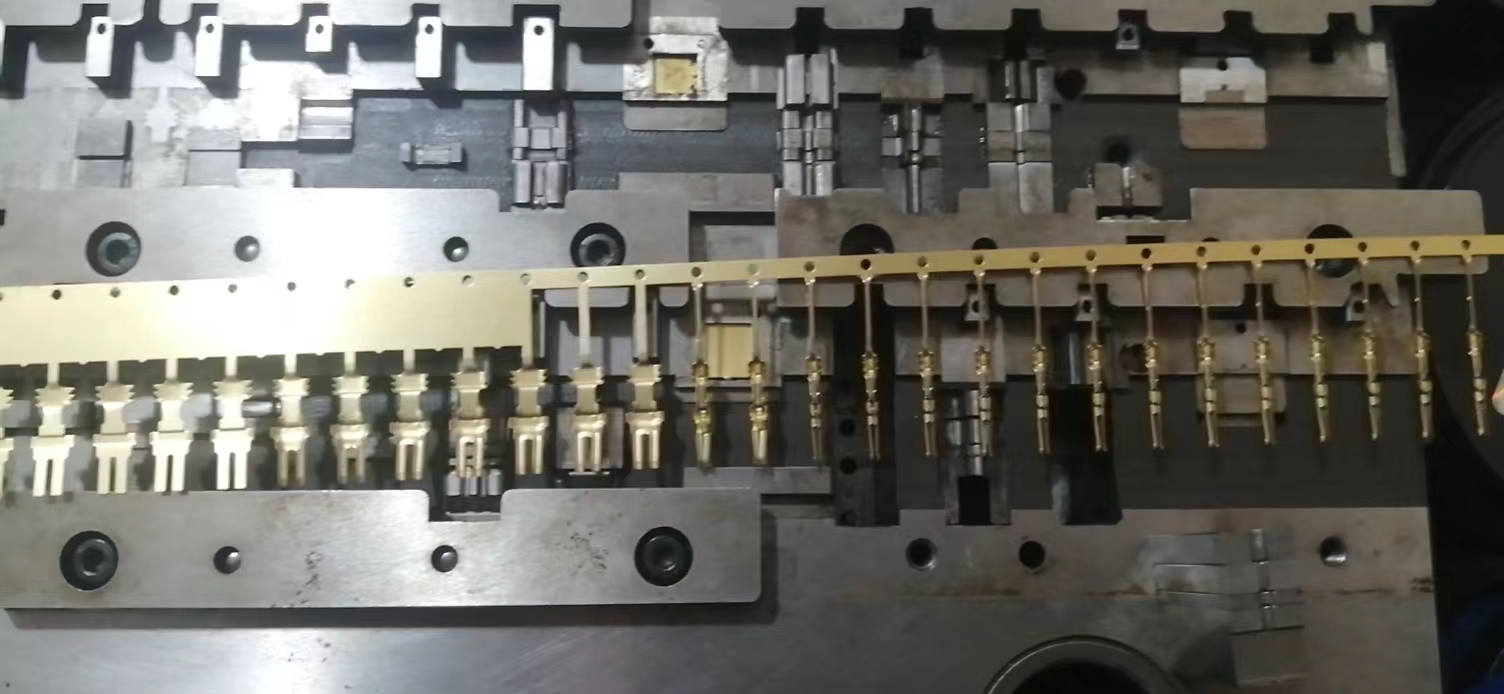

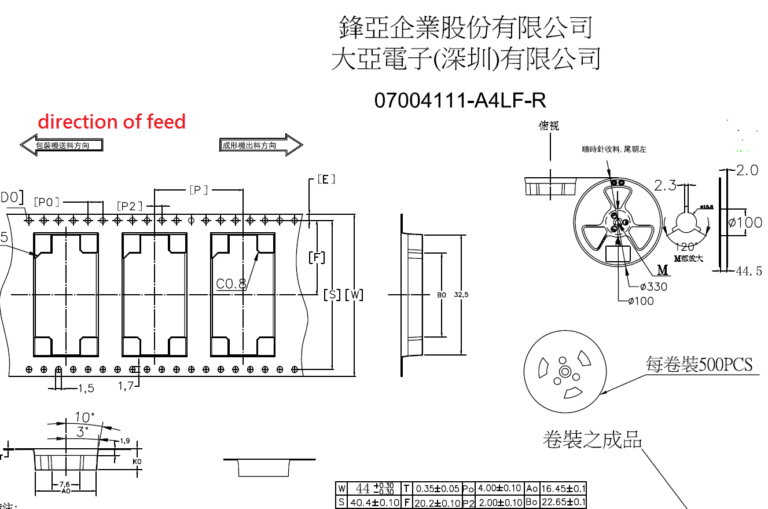

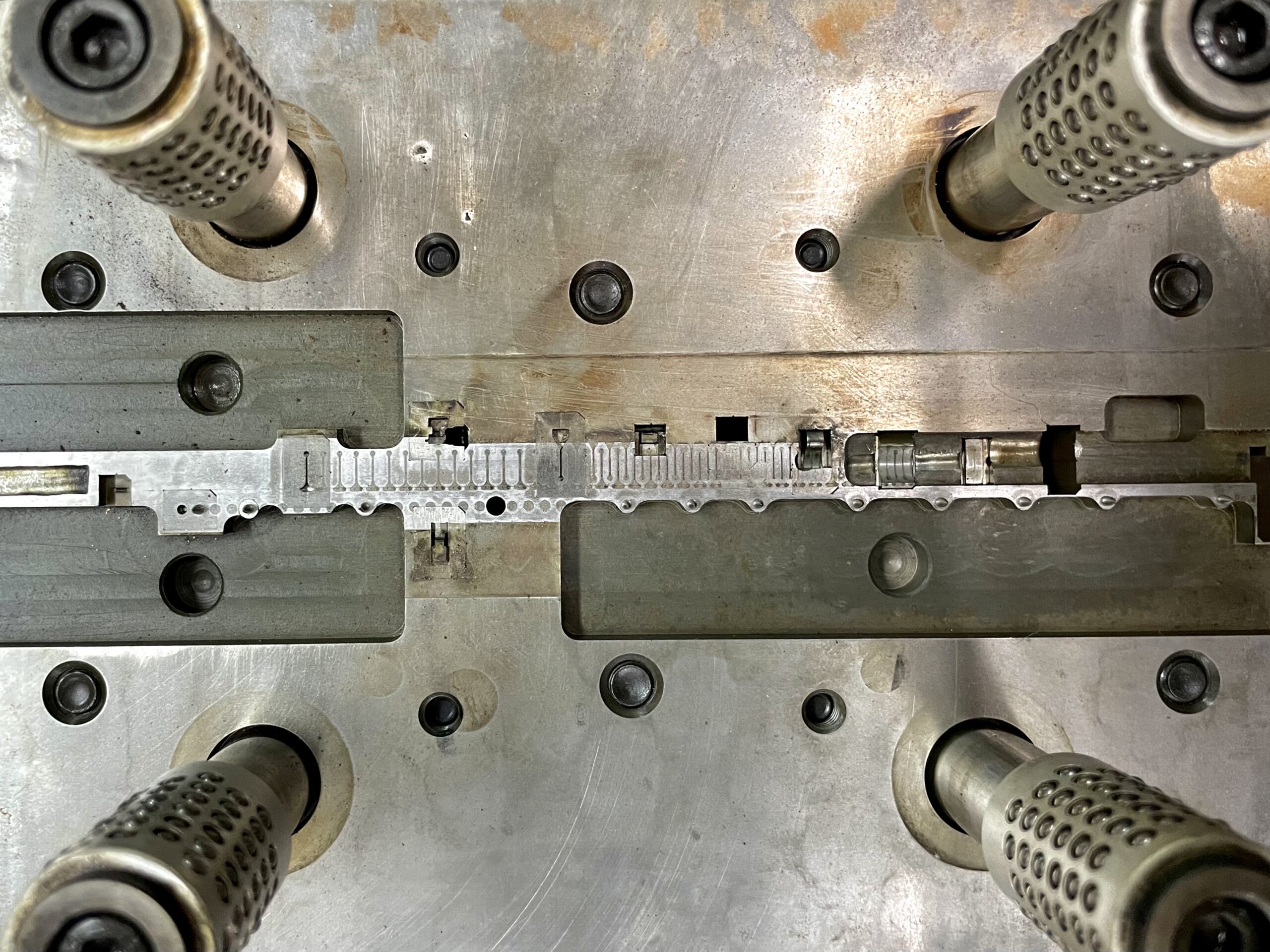

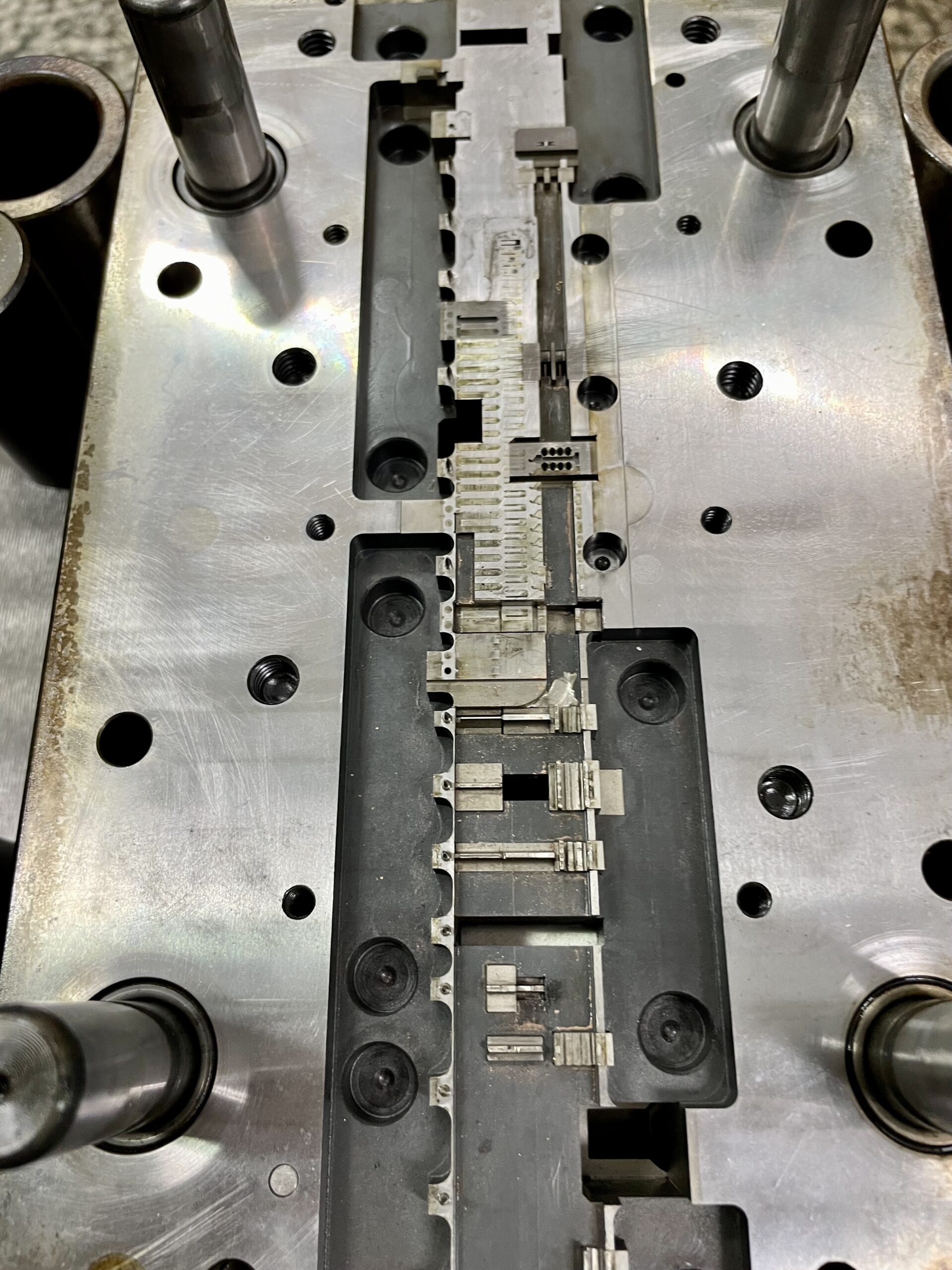

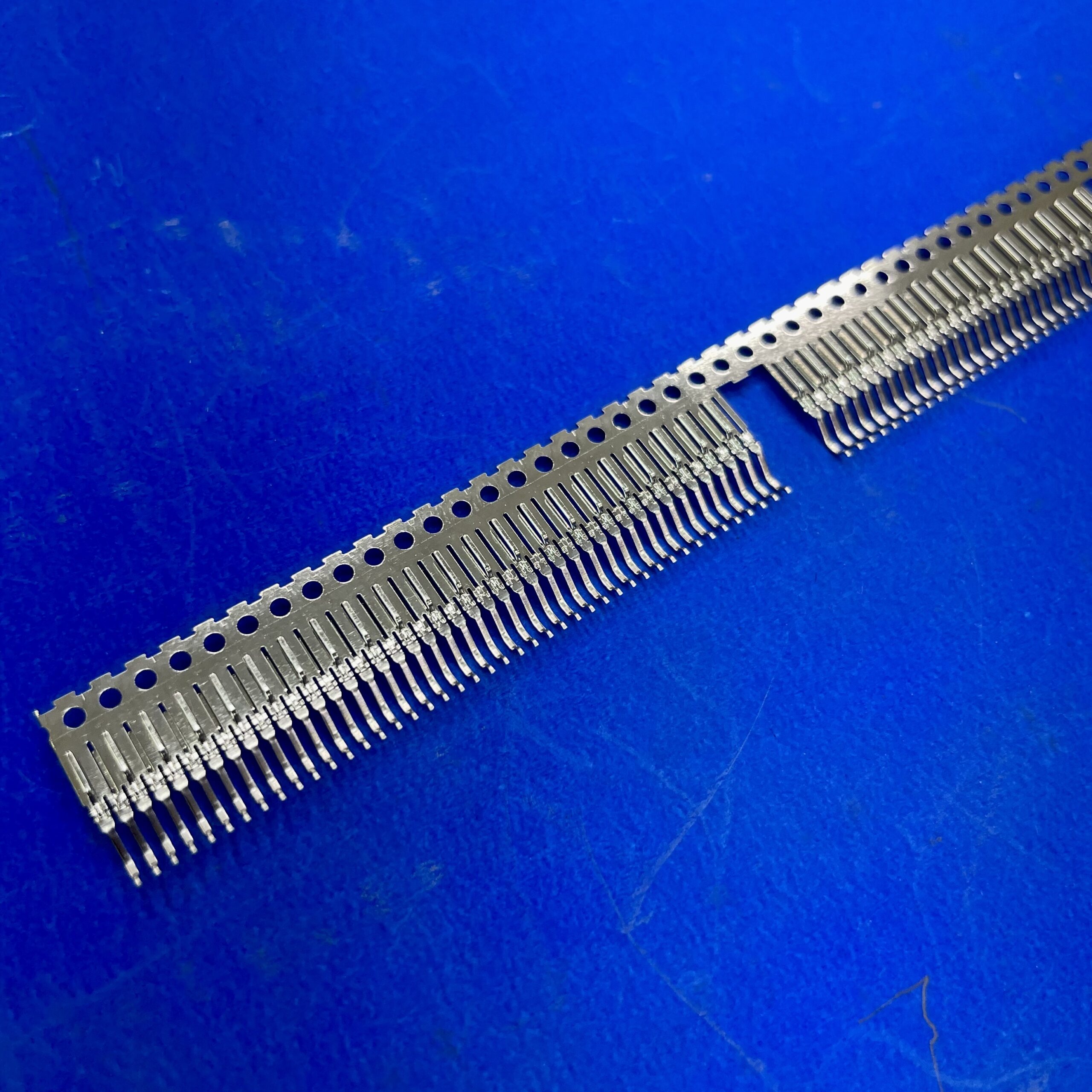

Stamp Mold

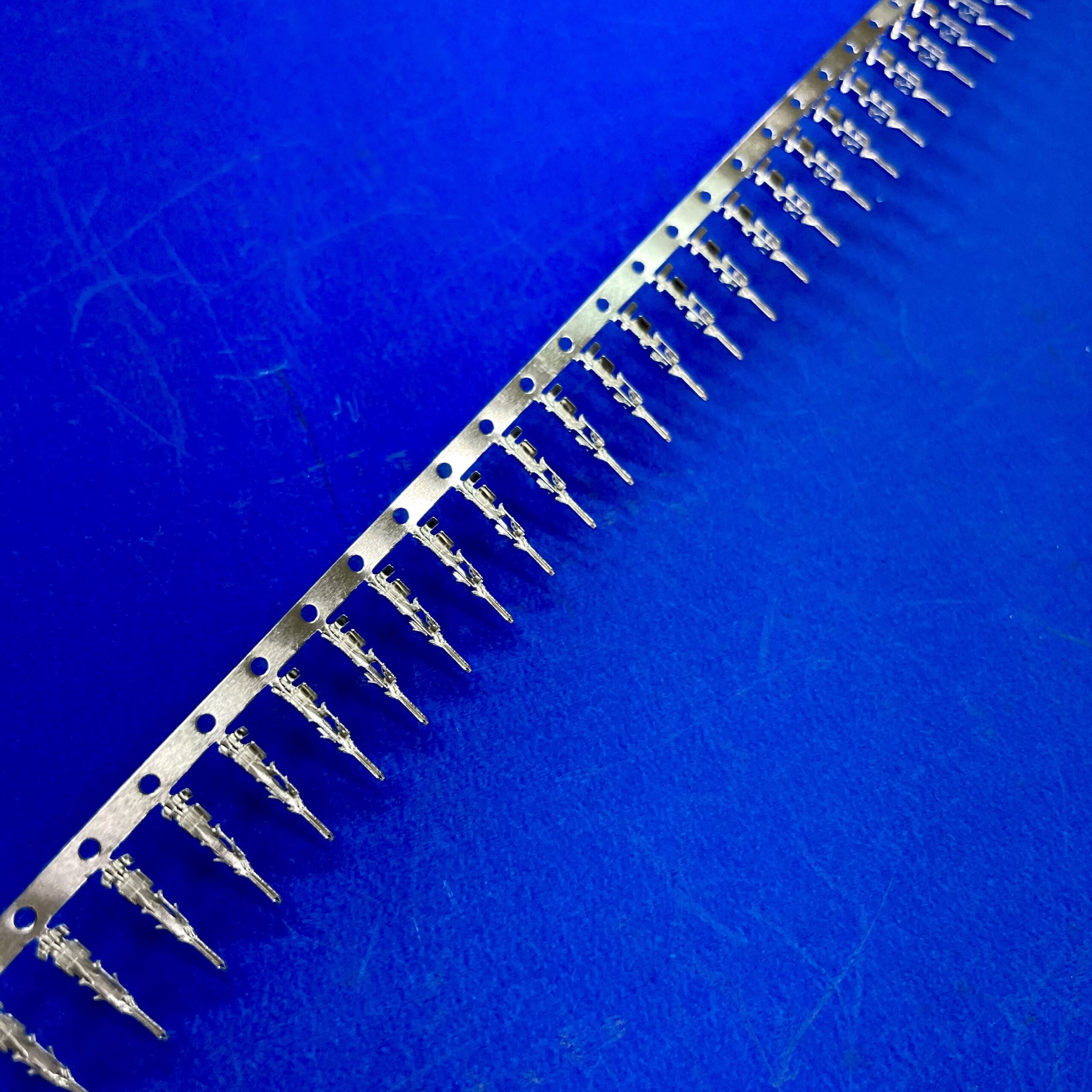

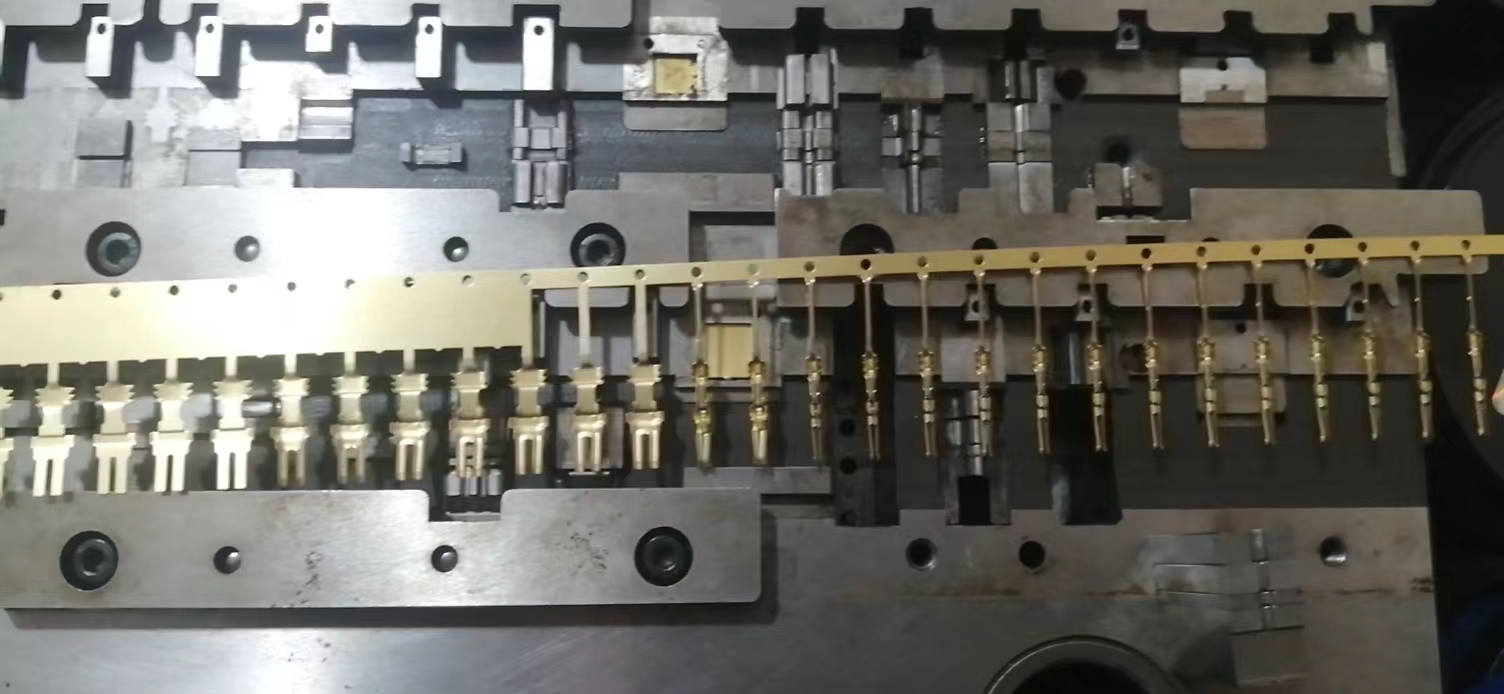

Using the power of stamping equipment to slam metal materials (copper or iron) to cut, bend or shape them into the finished shape and size specified by the mold. Stamping processing can be roughly divided into several different processing types such as shearing, bending, forming and extension.

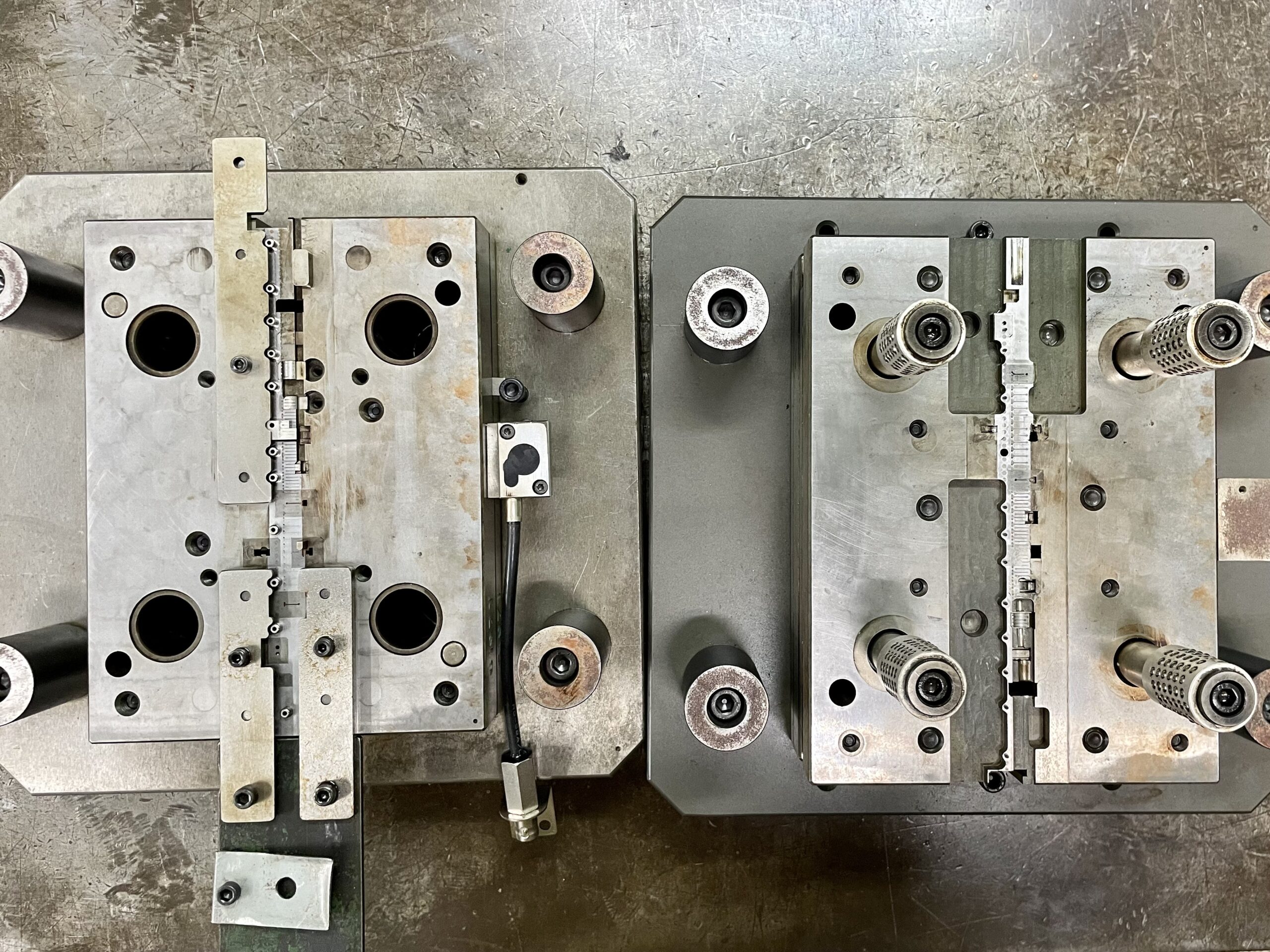

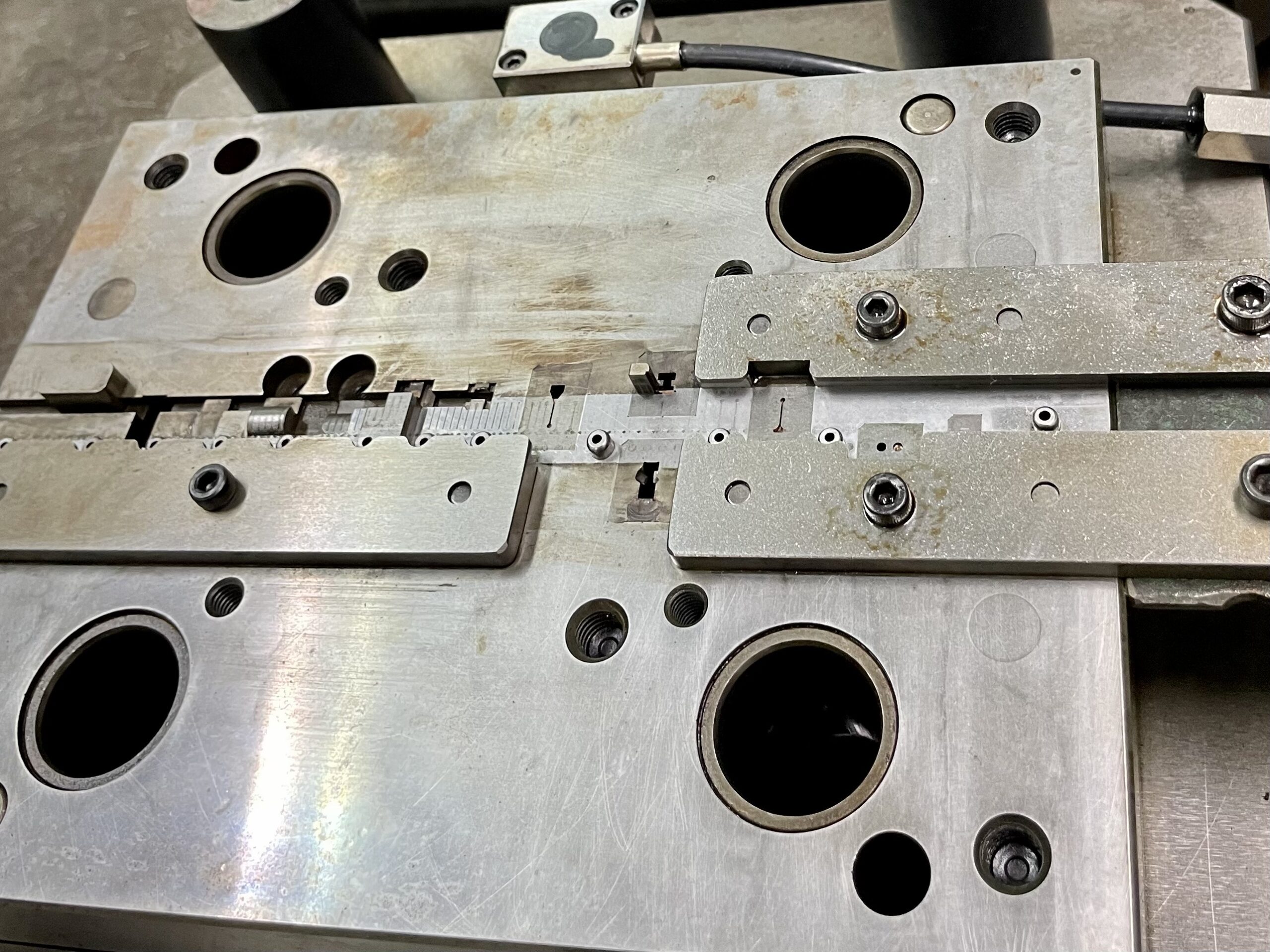

Creating a New Mold

We are happy to submit production cost assessment, mechanism analysis, rolling direction, material performance, 3D MODEL, FAI REPORT to customers, so that the mold can meet the cost requirements and mass production on time

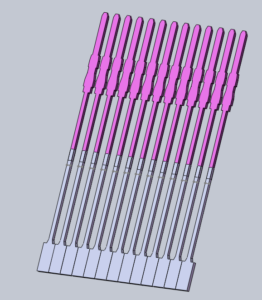

01. 3D Model

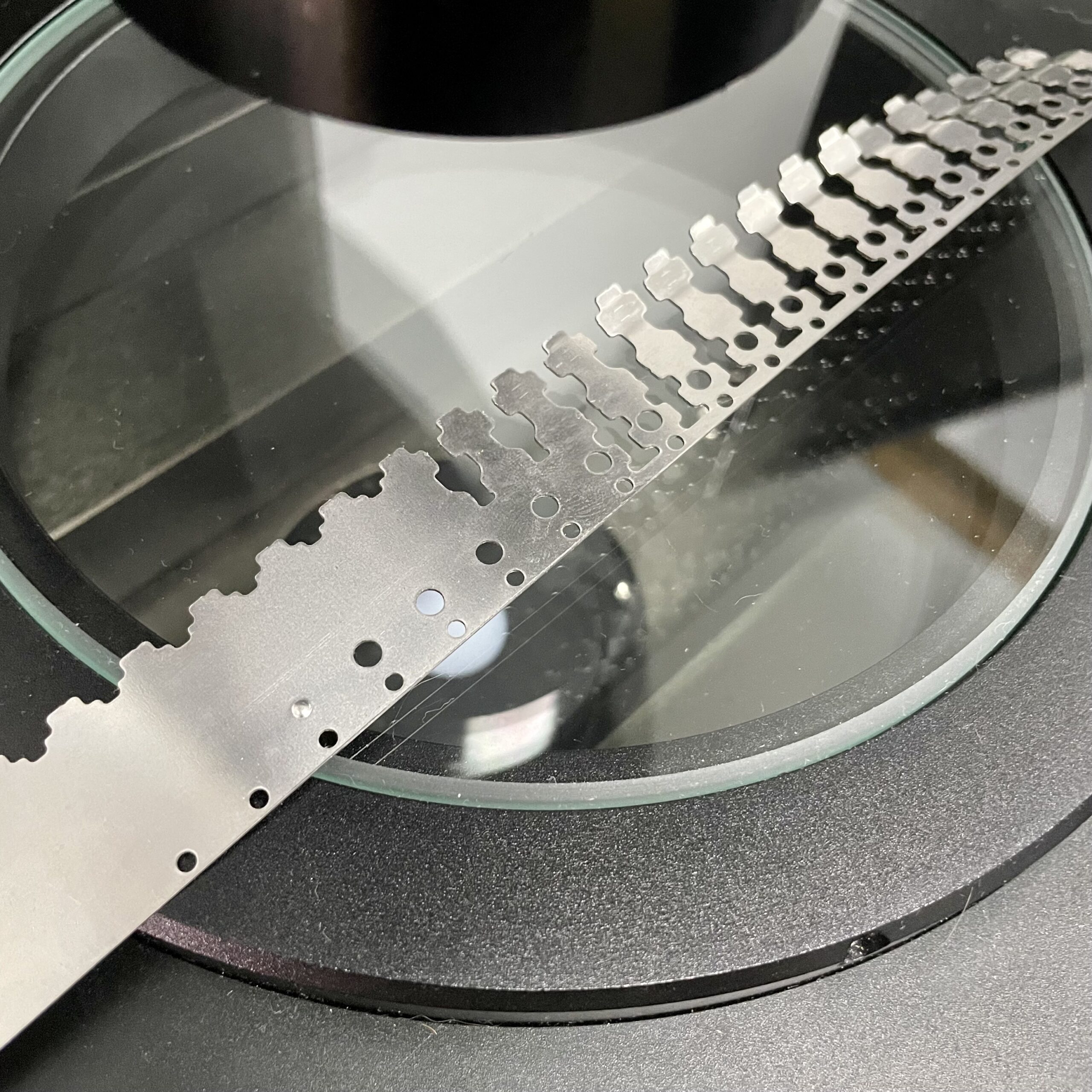

For customers who may not be able to actually grasp the real object because they only look at the 2D drawing, they can use the vivid “3D drawing” to understand the real appearance of the real object, such as checking the matching status of the terminal mechanism and the colloid, which can be presented more clearly

02. Rolling Direction

The setting of the rolling direction, in addition to affecting the elastic strength of the terminal, also has a key impact on the stability of the stamping size and the cost of materials.

03. handmade sample

Hand-made samples can provide a simulation equivalent to physical use, obtain preliminary confirmation of function and structure, improve design shortcomings and avoid repeated design changes, thereby reducing mold development costs. We actively analyze feasibility and provide hand-made samples to customers, so that Customers feel at ease and satisfied.

04. Select the Right Material

Use with right material is related to product cost, and it is even more important for product function and service life. For various demands (such as impedance, clamping life, hardness, ductility) we provide cheap and easy-to-obtain materials for customers to choose, so that Commodities have inherent advantages and win at the starting point.

Real Results, Guaranteed

Case Studies

Design Considerations

Let's Build Something Together

Trusted Manufacturer

Made in Taiwan

Engineers at ANYTRONIC® understand the complexities of beginning a new CNC Turning project and want to help you to bring yours to fruition. You can trust the experts at ANYTRONIC to take your product from concept to completion.

For more information on ANYTRONIC® CNC Turning and if it would be the right method for your part run, contact one of our manufacturing & engineering experts now.