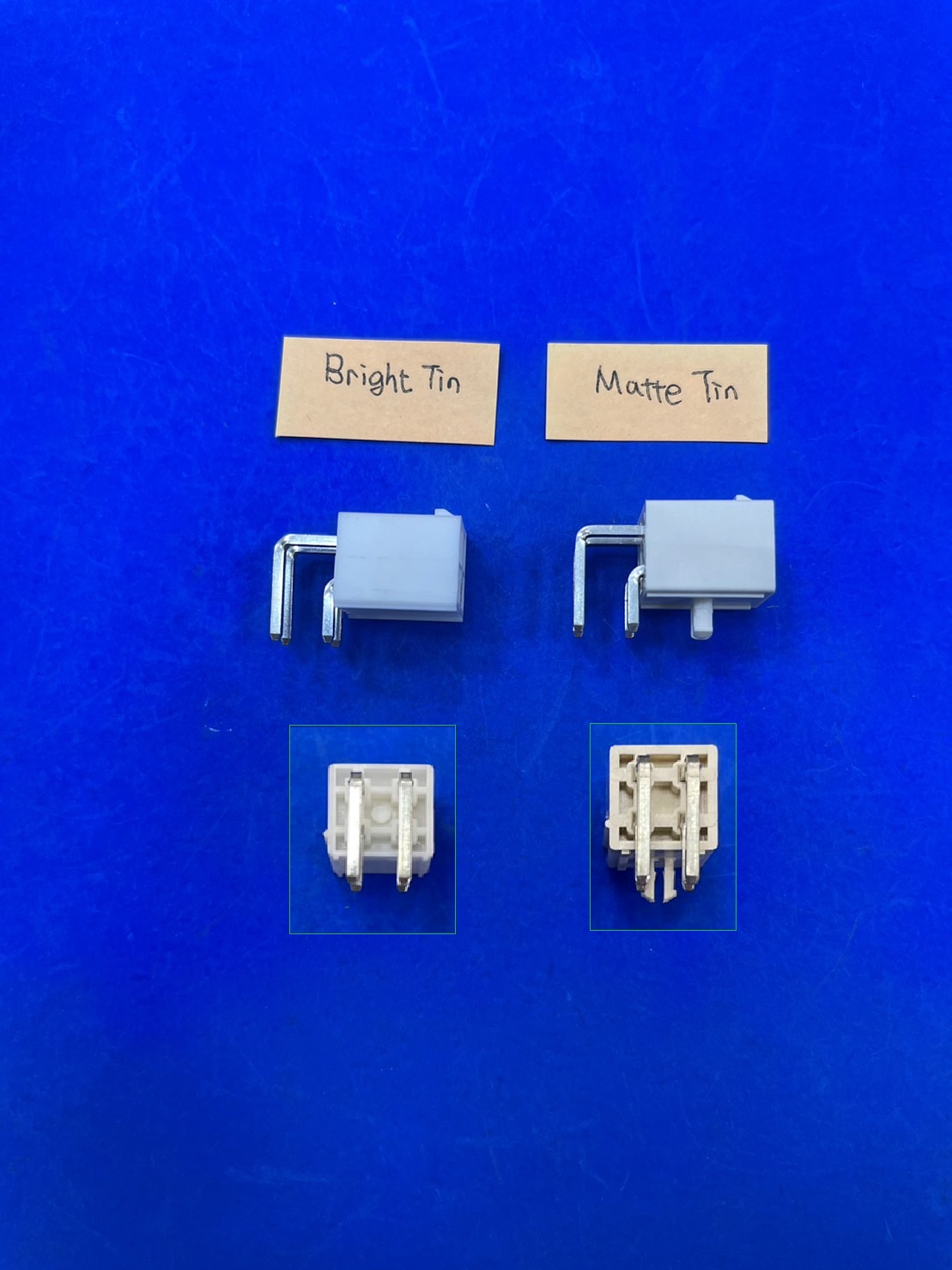

How to choose matte tin and bright tin for connector terminals? What is the difference between the two?

連接器端子有霧錫和亮錫如何選擇? 兩者有什麼不同?

The terminals of the connector are matte tin and bright tin, do you know the difference between them?

In order to comply with the RoHS and REACH specifications (restrictions on the Pb content of tin-plated products), the component manufacturing has introduced a new method to replace the original tin-lead surface treatment of electronic parts lead, so as to meet the new environmental protection soldering process requirements. Among them “Full tin plating” is further divided into two types: “Matte tin” and “Bright tin”. How to choose the type of tin plating to avoid quality issues during the soldering process, such as terminal yellowing, Tin layer avalanche, poor soldering (Deweting), false soldering…etc. It is obviously subjects that should be understood and paid attention to.

電子零件製造業為了符合RoHS和REACH規範 (對鍍錫品的含鉛量做了限制),出現了取代原本電子零件腳的錫鉛表面處理的新方式,以便能夠滿足新的環保焊錫製程要求, 其中「鍍全錫」又分為「霧錫(Matte tin)」及「亮錫(Bright tin)」2種,如何選用鍍錫的種類以便避免焊錫製程時的品質問題,例如: 端子變黃、錫層崩離、爬錫不良 (Deweting)、空焊、假焊…等,顯然是應了解及注意的課題.

In fact, the bright surface and the matte surface are the reflection and refraction of light on the object. The smoother the surface of the object, the more comprehensive the reflected light, so it will look brighter, otherwise it will become darker. So why is there a difference between bright tin and matte tin? The answer is additives. The surface roughness of tin is basically not much different, and the residue of additives can smooth the uneven surface, so that light can be reflected more comprehensively..

上述所提到的亮面與霧面,就是光線照射在物體上反射跟折射的表現,表面越光滑的物體,它的反射光線就越全面,所以看起來就會越亮,相反則變暗。同樣都是錫,會有亮錫及霧錫的差別在於添加劑,其實錫的表面粗糙度基本上差異不會太多,而添加劑的殘留可以撫平凹凸不平的表面,讓光線可以更全面的反射。