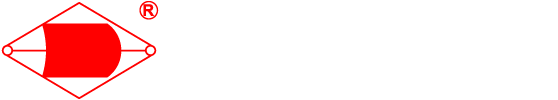

What is the PLCC SOCKET?

A PLCC SOCKET, also known as a PLCC SOCKT (Plastic Leaded Chip Carrier), is a socket used for the installation and connection of CHIPS (integrated circuit ICs). It typically consists of a plastic base and metal pins. The socket connector is mounted on a printed circuit board (PCB) using either Surface Mount Technology (SMT) or through-hole soldering (WAVE SOLDERING). PLCC SOCKET connectors allow for convenient insertion and removal of CHIPS, increasing the lifespan of the CHIPS and facilitating software updates.

Key Features and Applications of PLCC SMT SOCKET

Here are some key features and applications of PLCC SMT SOCKET:

Features:

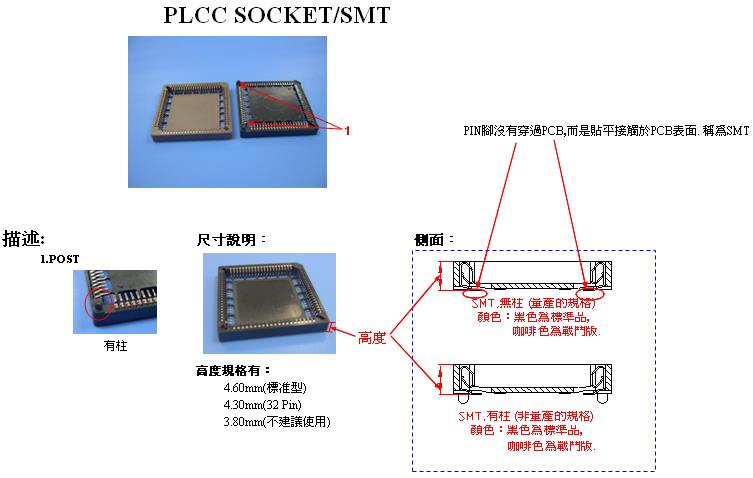

- SMT Technology Compatibility: PLCC SMT SOCKET is specially designed to be compatible with Surface Mount Technology (SMT), allowing them to be directly soldered onto the PCB without the need for through-hole soldering.

- IC Pin Compatibility: These sockets are designed with the pin arrangement of PLCC-packaged ICs in mind, ensuring that the connectors are fully compatible with the IC pins, thus ensuring a reliable connection.

- Removability: PLCC SMT SOCKET provides a convenient way for packaged CHIPS to be easily inserted or removed from the socket without the need for re-soldering. This is particularly useful for maintenance, replacing faulty ICs, or upgrading systems.

Applications:

- PLCC SMT SOCKET is widely used in various electronic equipment manufacturing and maintenance applications, including but not limited to:

- Electronics Manufacturing: PLCC SMT SOCKET is commonly used in the production and assembly of electronic devices for convenient IC installation and replacement.

- Communication Equipment: Used to connect PLCC-packaged ICs in various communication equipment such as routers, switches, etc.

- Industrial Control Systems: In industrial automation and control systems, PLCC SMT SOCKET can be used for easy replacement of faulty controllers or modules.

- Automotive Electronics: In automotive electronic systems, PLCC SMT SOCKET can be used to connect vehicle control units (ECUs), among other applications.

Common Specifications of SIMM SOCKET.

Introduction to the Specifications and Component Names of PLCC SMD SOCKET

Here is a brief overview of the specifications and component names of PLCC SMD SOCKET:

Socket Type: This refers to the specific type of PLCC SOCKET, such as 20P, 28P, 32P, etc.

Material: PLCC SMD SOCKETs can be made from various materials, including PPS (Polyphenylene Sulfide) and PBT (Polybutylene Terephthalate).

Height: Different PLCC SMD SOCKETs come in various heights to accommodate different applications and IC sizes.

These components and specifications are crucial in selecting the right PLCC SMD SOCKET for your electronic device or application.

Where to Buy PLCC SMT SOCKET

PLCC SOCKET is a well-established product with specifications including 20P, 28P, 32P, 44P, 52P, 68P, and 84P. Manufacturers of PLCC SOCKETs in Taiwan such as Chih-Kang Industrial Co., Ltd. (中志工業股份有限公司) and Anytronic Corporation Limited (ATRC) have been producing them since 1988. These sockets are made from materials like PPS and PBT and are available in various heights. Their products are widely used in electronic devices, including motherboards, modems, and more.